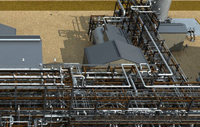

Refinery Fluid Catalytic Cracking (FCC) Unit Debottlenecking

Baiji Refinery, Iraq, contracted Firebag Technical Solutions to review their Fluid Catalytic Cracking (FCC) main fractionator performance. The FCC data was showing very poor separation efficiency between its three liquid products and large differences between set and reported temperatures with increased elevation of the tower. In addition, the thermocouples were reporting flipping temperatures at unpredictable intervals several times per month and the flipping would propagate rapidly through the tower beds, making it difficult to determine where they were originating.

A Hysys simulation model of the process was developed to characterize the reactor feeding stream and calculate proper equipment sizing based on operating conditions and material balance. Also, we reviewed the unit drawings and compared its measurements with the results of developed Hysys model. This actually showed the slurry bed liquid distributor had a design malfunction in distribution of vapor to the top of the tower, which would initiate temperature flipping.

Firebag Technical Solutions designed two new bubble cap trays to ensure even distribution of vapor in the fractionator. In addition, we recommended that the tray at the feed zone of the tower be changed with a with a chimney tray design to prevent weeping of liquid in case of low vapor pressure.